LİMAK DOĞAL GAZ ELEKTRİK ÜRETİM A.Ş. REPLANTING PROJECT

Limak Natural Gas Electricity Generation Inc. intends to carry out renovation works at Hamitabat Natural Gas Combined Cycle Power Plant (HPP) to continue generating electricity through its affiliating company, Hamitabat Electricity Generation and Trade Inc. (HEAS).

The objective of the renovation works at HPP, which is coming to the end of its operational life, is to continue generating sufficient and reliable electricity with less environmental influence and to provide sustainable operation by improving the energy generation efficiency and reducing the emissions of air pollutants.

The total operational capacity of the plant is 1156 MW and as a result of the investments Limak Energy is planing to transform Hamitabat into the most efficient power plant of Turkey.

The electricity generation licence granted by EMRA for the project, which is planned to be set into operation in 2017, is valid for 49 years; however, the economical term of the project is considered as 30 years in line with the 30 year period accepted for the benefit-cost analyses of the project. This term can be prolonged by repair, maintenance and renovation works to be conducted.

The fuel used at HPP is natural gas and it is supplied from BOTAŞ Petroleum Pipeline Corporation via 36” Russia-Turkey Natural Gas Pipeline and it is transported to the facility via the existing 20” branching line with an approximate length of 800 m. A new branching line will be laid along the route of existing branching line in the course of the renovation works.

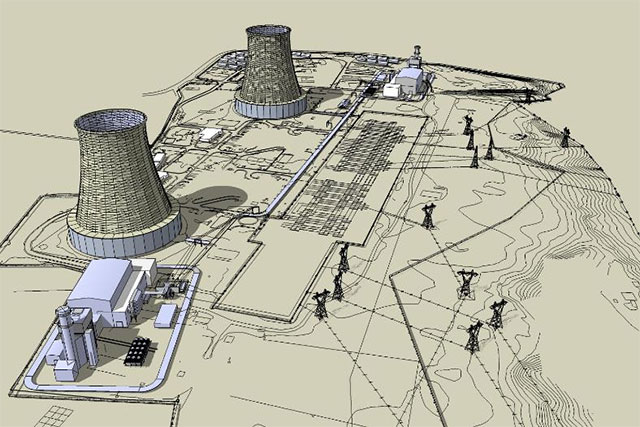

The generated electrical energy will be transferred via 154 kV and 380 kV lines at the existing Hamitabat switchyard, where the national and international network systems are bridged and it has 154 kV and 380 kV switchyards, two groups of main bus and transfer bus systems.

In the scope of the renovation works at HPP, two combined cycle blocks will be renovated. Each combined cycle block will contain one gas turbine , one steam turbine having high, medium and low pressure stages and one generator. Accordingly, there will be two gas turbines, two steam turbines and 2 generators in total at the facility; moreover, one heat recovery steam generator, one condenser and one main cooling system at each cycle block.

The gas turbines at the facility will be air cooled; therefore, no water consumption will be of concern. On the other hand, the steam turbines will have closed cycle water cooling system and will be cooled via hot water cooling towers. Two existing cooling towers of HPP will be refurbished and used as the main cooling water system.

As it can be seen from the general layout plan, one of the combined cycle block is planned to be established close to the cooling tower and administration building at the north of the project site; while the other block is planned to be established close to the second cooling tower at the south of the plant. The area where the renovation works will be carried out is the existing HPP site; no additional new site will be used.